King's Award for Excellence for Innovation 2023 WINNERS.

PALLITE® PIX® warehouse storage units for e-commerce fulfilment, shipping crates, layer boards, protective packaging and pallets

100% Recyclable

Storage Bins, Shipping Crates and Packaging Designed to your Specifications

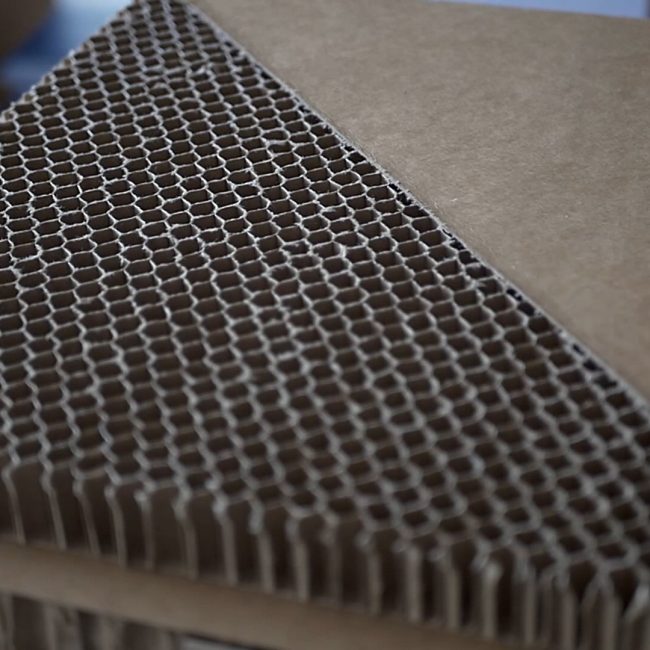

All PALLITE® products are produced from honeycomb paper cardboard and are 100% recyclable. We are experts in developing and tailoring solutions specific to our customer’s supply chain requirements.

From paper pallets, shipping crates, sustainable packaging and void fill to our PIX®, PIX® SLOTS and PIX® XL Bin Box warehouse storage bins for e-commerce fulfilment.

Our in-house team of professionals have the expertise to advise businesses on how they can implement a flexible warehouse storage solution or protective packaging sustainable option.

Flexible Storage Units for all SKU sizes

Suitable for E-commerce Fulfilment, 3PLs, 4PLs

Our range of lightweight, flexible and strong warehouse storage bin and shelving systems are designed to consolidate space and adjust to changing stock requirements. Our manufacturing facilities have the versatility and capability to produce PIX® and PIX® SLOTS warehouse solutions specific to each customer’s needs. From small accessories to larger apparel there's a picking solution to suit all 3PL and e-commerce fulfilment centres.

Available with 3 up to 400 pick faces, all our storage solutions can be built in minutes with no expertise or tools required.

100% Recyclable Products

Sustainable Products for Logistics, Packaging and Warehouse Storage

PALLITE® use ethically sourced paper, a sustainable and renewable resource that is significantly better for the environment than virgin paper. In the UK, more than 80% of paper is recycled by end users and used to make new products, saving energy, reducing water pollution and lowering air pollution.

PALLITE® products are not only environmentally friendly but technically advanced in their functionality. Fulfilling on your sustainability goals does not mean a loss in strength or performance.

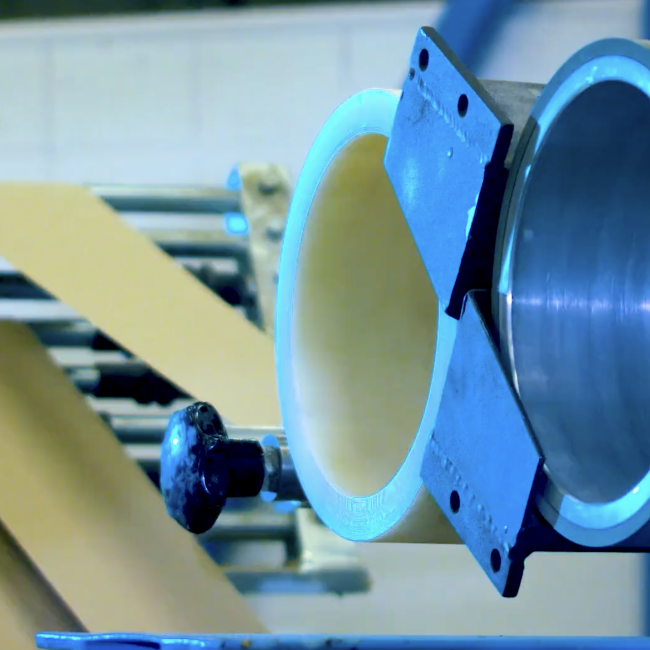

Manufactured in the UK

Incredibly strong yet lightweight paper pallets, shipping crates, boxes and layer boards are designed to reduce the total cost of shipping consignments, while boosting organisations’ green credentials. Stronger than standard cardboard pallets and boxes, they carry heavy loads with ease.

Change from traditional wood pallets to our honeycomb paper cardboard pallets and shipping crates for an ISPM15 exempt solution and a guaranteed supply of product with short lead times.

Work out your CO2 Savings for your supply chain with our PALLITE® Sustainability Calculator by clicking below.

Pallets, PIX® Warehouse Storage and Packaging

STRONG AND SUSTAINABLE PALLETS, SHIPPING CRATES AND WAREHOUSE STORAGE BINS

Does changing to a paper pallet or PIX® paper-based warehouse storage solution mean a reduction in strength?

NO, the technology behind the structure of our core material, honeycomb paper cardboard, provides for finished products that often outperform many well-known traditional alternative materials.

PALLITE® pallets are strong enough to hold up to 750kg

PALLITE® PIX® warehouse storage units are strong enough to hold up to 500kg

PALLITE® shipping crates can hold up to 750kg and stack up to 500kg

Green alternative to foam, plastic and polystyrene packaging

SUSTAINABLE PROTECTIVE PACKAGING AND VOID FILL

EcoLITE by PALLITE® is our range of sustainable packaging and void fill offering businesses a cost-effective and sustainable alternative to foam, plastic and polystyrene packaging.

PALLITE® can provide a packaging solution specific to your product requirements, whether it be our easy to tear off honeycomb cardboard pads for void fill, edge protectors, box liners or a tailor-made protective packaging design. Our UK based manufacturing facility has the capabilities to respond quickly to your needs and with short lead times.