Manufacturing

QUALITY PRODUCTS PRODUCED T0 EXACTING STANDARDS

QUALITY PRODUCTS START WITH QUALITY MATERIALS.

As a manufacturer we recognise the importance of producing products that are of a consistently high quality. Products that can be trusted for their functionality and durability.

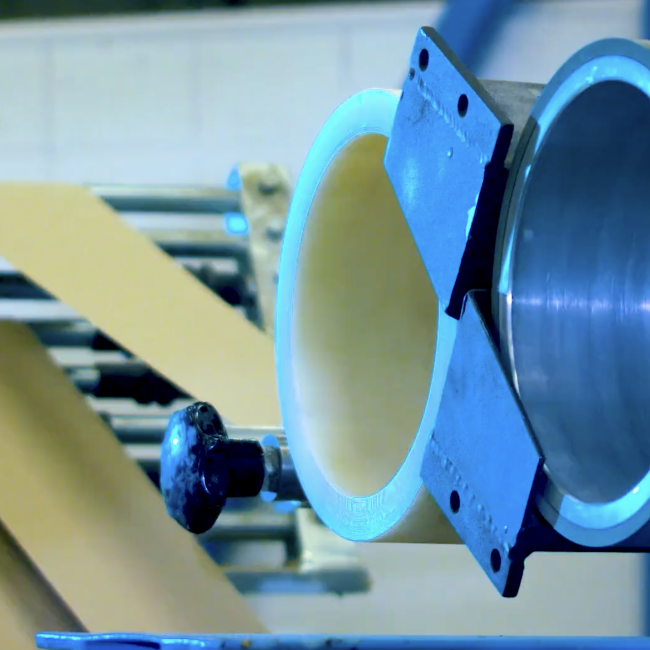

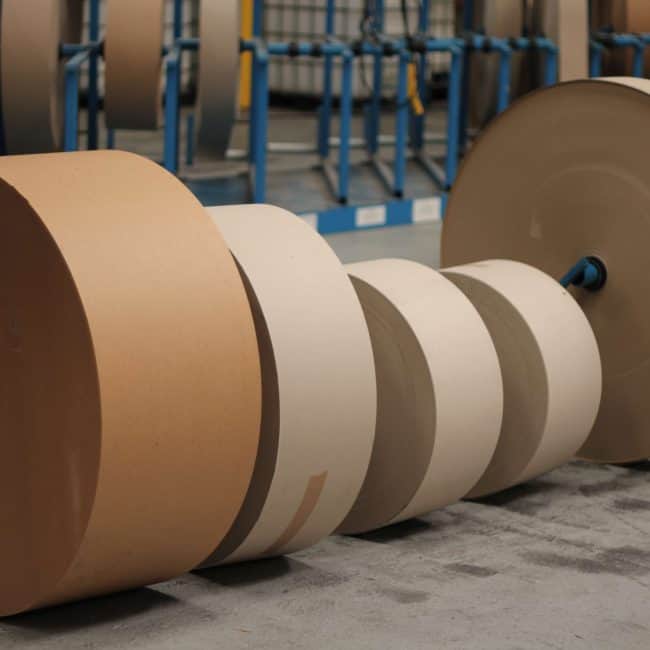

We perform qualitative and quantitative quality checks on every reel of paper that enters our warehouse. Performing these tests helps ensure that any faults at this stage don’t enter the manufacturing process and ultimately end up in your supply chain.

OUR PAPER TESTS INCLUDE:

- Visual check – paper fibre size, contamination to the paper and tears

- Grammage of the paper

- Thickness of the paper

- Cobb rating – absorbency of the paper

We work with some of the leading paper manufacturers in the world, who also work to the highest quality standards.

If we create a specification that’s new or we’re testing a fresh, innovative idea, we’ll perform functionality testing and validation to guarantee the products are fit for purpose. This is either performed in house or by an accredited third party.

THESE TESTS CAN INCLUDE, BUT ARE NOT LIMITED TO:

- Board deflection

- Stress point testing

- Load/weight validation

QUALITY PRODUCTS PRODUCED TO THE HIGHEST STANDARDS TO MEET OUR CUSTOMER'S SUPPLY CHAIN REQUIREMENTS.

EMPHA

We are a member of EMPHA, the European Manufacturers Paper Honeycomb Association, the pan-European association for manufacturers of paper honeycomb core and paper honeycomb board products.

Founded in Amsterdam in 2010 EMPHA represents the paper honeycomb industry and includes a Technical Task Team to address the issue of Voluntary Technical Standards.

The goal for this committee is to create a set of technical standards and methods that can be used to create and maintain transparent and measurable parameters that define the specific quality of the paper honeycomb.

These standards include:-

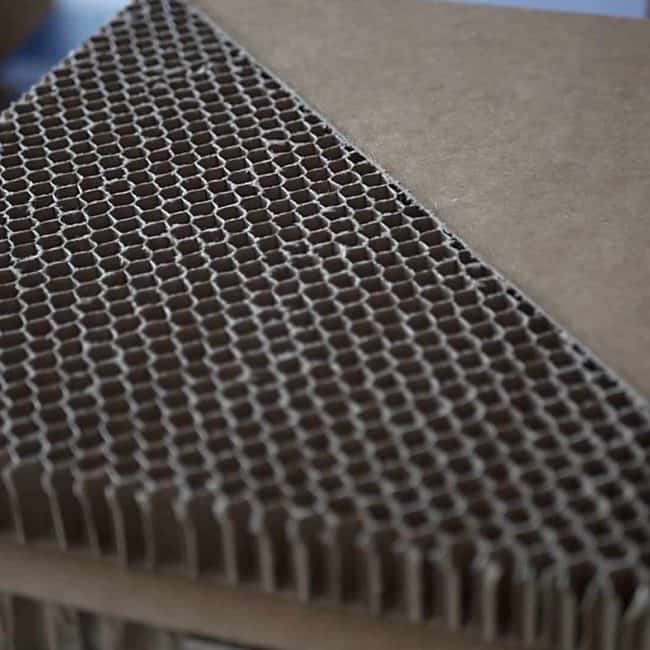

- Compression strength

- Honeycomb cell geometry

- Height of the cells

- Paper honeycomb cell panel uniformity

Why Honeycomb?

Honeycomb is noted for its superior strength, rigidity, reduced weight and minimum environmental impact.

Honeycomb is noted for its superior strength, rigidity, reduced weight and minimum environmental impact.

The world of logistics needs solid and stable support materials to optimise the storage and transportation process and contribute to a better financial logistics performance. Paper honeycomb has successfully contributed to these challenges in transport and logistics for many years.

Solutions for transport and logistics include paper honeycomb pallets, product spacers, void fillers, edge protectors and corner protectors. They contribute to the process of securing the product, avoid damage in the logistic chain during storage and transportation whilst providing considerable environmental benefits.

Additional benefits of Honeycomb

With a superior combination of strength to weight ratio, honeycomb paper pallets for example are 60-80% lighter than conventional pallets, saving on shipping costs, maximising loads and contributing towards huge CO2 reductions.

In addition to the weight advantage, paper honeycomb has several additional benefits:-

- Nail and splinter free

- ISPM15 exempt - do not require heat treatment for export.

- Hygienically produced to provide a cleaner protection for the transport of food and pharmaceutical products

‘PALLITE® are great, we have worked with them not only using their pallets but also the flexible PIX® location.They also supported with screens for our counter staff at the start of Covid where many companies struggled to provide solutions.

British Airways Engineering

New Machines

Greater Capacity, Lower Production Cost, Shorter Lead Times.

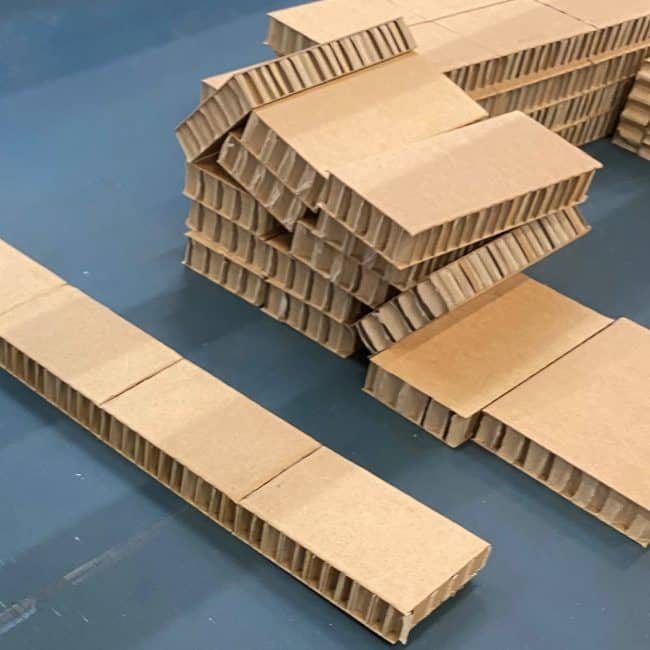

Our CNC and slitter machines can manufacture standard and bespoke designs to short lead times.

The recent addition of a new slitter machine has transformed the production of more simple profiles and freed up the CNC machine for more complex components. We are now able to provide the following products at even lower costs:-

- Honeycomb board strips and planks providing us with even more sustainable alternatives.

- Sheets of honeycomb board can be produced efficiently and quickly for simple ‘snap off’ shapes to replace polystyrene or foam packaging and void fill.

- Larger, folded rectangular shapes can be turned around to meet tight deadlines.

Faster lead times

This new machine not only means faster lead times for our EcoLITE void fill products, but it will also reduce even further, PALLITE®’s and your negative impact on our planet. ????

To learn more about EcoLITE honeycomb void fill, our foam and polystyrene sustainable alternative, click the link below.